Sep 30, 2013

The shale shaker is the first stage solids control equipment in drilling purification system. It can remove cuttings above 75μm brought from the drilling well to leave the liquid with smaller particles into the tanks below, which will flow into next solids control equipment for further treatment.

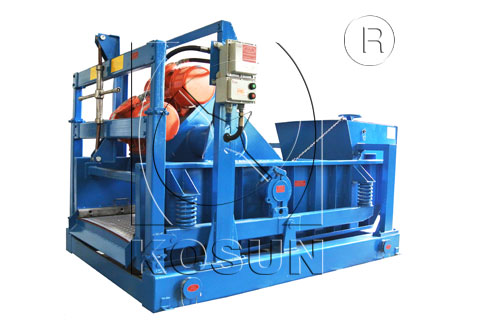

Shale shaker is the first phase solids control equipment in drilling fluids processing system, also known as key solids control equipment in drilling mud system, shale shaker decides performance of the whole solids control system. KOSUN can design double shakers and triplicate shakers on single skid according to clients’ special requirements and also supply relevant connecting manifold, according to current industry situation, KOSUN provides both of them and the balanced elliptical shale shaker.

Shale shaker for solids control is the device that removes drill cuttings from the drilling fluids while circulating and drilling. There are many different designs and research into the best design constantly ongoing since solids control is vital in keeping down costs associated with the drilling fluids. The basic design consists of large, flat sheets of wire mesh screens or sieves of various mesh sizes that shakes or vibrates the drill cuttings, commonly shale shaker, across and out of the screens as the drilling fluids flows through them and back into the drilling fluids processing system, often called a mud system. This separates the drill cuttings, often called solids, from the drilling fluids so that it can be recirculated back down the well bore. In oilfield industry, linear motion shale shaker is widely used for drilling mud solids control of oil & gas well drilling for rig.

High G-force in a shale shaker is essential to convey the amount of cuttings generated while drilling a bore hole, to properly dewater drill cuttings, to reclaim in expensive drilling fluids, and to minimize drilling fluids waste. While drilling top-hole sections, where heavy, high-volume cuttings are typically encountered, shakers need to generate high G-force to effectively convey dense solids. KOSUN Variable Linear Motion Vibrator Motors are designed to give the operator the ability to adjust the G-force of the shaker to perform under high solids loading conditions and when managing reactive, sticky, or fine solids. As conditions change in drilling and fluids, the G-force of KOSUN's shakers can be adjusted with the simple twist of the wrist at the control panel, therefore changing the cuttings conveyance velocity. This can be done without shutting down the shaker and adjusting the weight settlings on the vibrator motors saving time and cost on the work site.

In addition, KOSUN provides all the other solids control equipment as the requirements of customers, such as mud cleaner, decanter centrifuge, desander, desilter, mud tank, shear pump, centrifugal pump, complete solids control systems, drilling waste management equipment, etc.