Oct 16, 2013

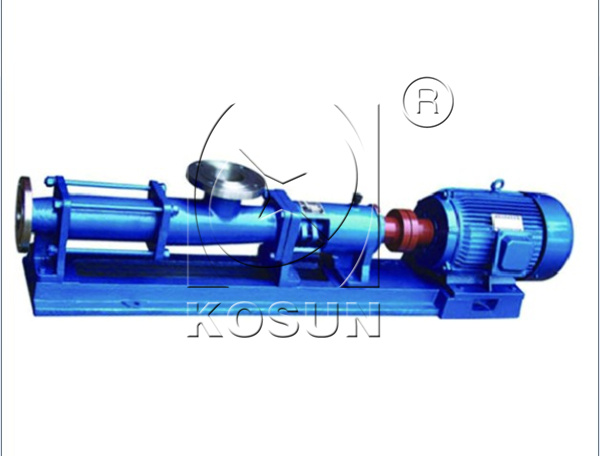

Screw pump, submersible slurry pump and centrifugal pump can be used for feeding decanter centrifuge in the drilling waste management system or solids control system. Screw pump in oil production is a kind of positive displacement pump, moving part is only threaded rod, without valve and complex flow channel. Oil flow less disturbance, thus greatly reducing energy loss. It has small size, light weight, less moving parts, uniform displacement and it is easy to manufacture and convenient to maintain.

First, select the screw pump rotational speed:

There is a linear relationship between the flow and speed of the screw pump. Compared with low-speed screw pump, high-speed screw pump can increase the flow and lift, but it significantly increases power and its high-speed accelerates abrasion between the rotor and stater. And the screw pump of the high rotational speed has veru short stater and rotor, which are easy to wear, thus shortening the service life of a screw pump.

Second, ensure that debris does not enter the pump:

Solid debris mixed in the drilling mud can damage the rubber material of the screw pump stater so as to ensure that the debris does not enter the pump.

Third, avoid breaking material:

KOSUN Screw Pump is not allowed to operate in the case of feed off. Once occurred, the rubber stator could generate high heat and burn out. So, grinder intact and grille unimpeded is the necessary conditions for the normal function.

Fourth, maintain a constant outlet pressure:

KOSUN Screw Pump is a positive displacement rotary pump. Pressure will gradually rise if the outlet end is blocked, even over a predetermined pressure value. The motor load increase quickly. Transmission machinery parts load will exceed the design value and burn transmission parts.