Cuttings equipment is an important part of closed-loop mud systems, which can recover more valuable

drilling fluids and reduce waste emissions. Reduce drilling costs and protect the environment.

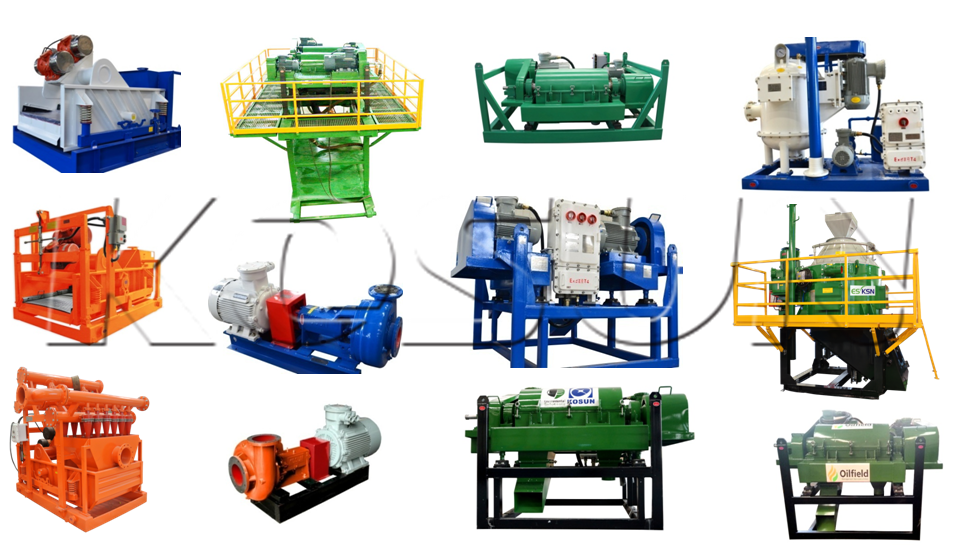

KOSUN can not only provide a single equipment, haier can provide different types of equipment including

the drilling cuttings processing system. Vertical cuttings dryer and settling centrifuge are the key equipment of cuttings processing system.

For

oil-based drilling cuttings,

the vertical cuttings dryer is ideal for separating drilling fluid from cuttings. The desiccant unit receives cuttings from solid controlled shaker to effectively reduce cuttings oil to 5%.We use a high hardness scraper to push the separated chips off the screen.High quality scraper ensures stable performance of drying device and low maintenance cost.

KOSUN is capable of providing vertical cuttings dryers and centrifuges with either fixed speed or variable frequency control modes. Sludge vacuum pumps and screw conveyors for cuttings, vertical dryers and high-g drying screens for cuttings dewatering, and high-speed centrifuges for cuttings separation.

Features and advantages of vertical cuttings dryer:

1. Efficient

solid-liquid separation can minimize the mud content in the cuttings and reduce the disposal amount of wastes;

2. Effectively separate and recycle mud in greater proportion, and reuse mud in the mud circulation system, which can recover mud lost due to shaker slurry, moving derrick and screen blockage;

3. Common wear can be replaced from the top of the device; The belt can be replaced without moving any device;

4. Tungsten carbide anti-corrosion and wear-resistant material is sprayed on the scraper of internal rotating body, which can prolong its service life and reduce maintenance cost.