Sep 10, 2013

How to dispose of drilling cuttings is one of the problems facing the oil and gas industry. Oil & gas drilling operation generated large volume of drill cuttings. Drill cuttings are produced as the rock is broken by the drill bit advancing through the rock or soil. Mud is circulated through the drill bit to lubricate and cool the bit. Drilling cuttings are usually carried to the surface by drilling mud and separated out by mechanical means, such as, shale shaker, mud cleaner, etc.

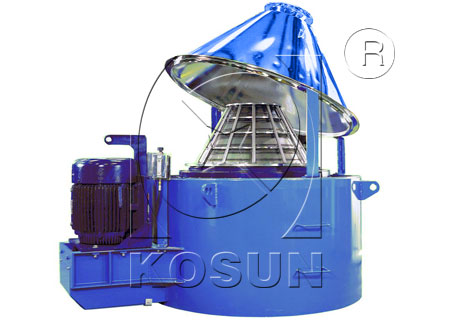

Vertical centrifuge is also called vertical cutting dryer, it is an innovative design which fits for oil-based drilling waste management. Drilling cuttings from the primary solids control equipment like shale shakers or mud cleaners are picked up by auger ( screw ) conveyor and transfered to feeder of the vertical cutting dryer.

The KOSUN Vertical Centrifuge returns and recycles large proportion SBM ( Synthetic Base Mud ) and OBM ( Oil Base Mud ) to the purification system, which in the past was regarded as waste dumped to the surroundings. KOSUN Vertical Centrifuge can lower cutting OOC than 6%, the current discharging limit in many areas of the world, however, our goal is to make it lower than 5%, and even further.

Features & Benefits

1. Highly effective liquids/solids separation minimizes fluids content of cuttings and reduces waste-disposal volumes.

2. Effective separation reclaims high percentages of fluids that can be reused in the active mud system, recovers whole mud lost from shaker failure, rig motion and screen blinding.

3. Normal wear parts are easily accessible from the top of the unit; belt is easily changed without having to remove assembly.

4. Interchangeable tungsten-carbide rotor blades and gear box prevent excessive erosion and minimizes the losses on main components.

The effective equipment for drilling cuttings disposal is vertical cutting dryer which can reduce the amount of OBM or SBM on cuttings discharge to reduce waste volume. Vertical cutting dryer uses centrifugal force to dry drilled cuttings coming from shale shaker or mud cleaners. The cuttings are conveyed to the dryer through vacuum transfer or screw coneyer. Once cuttings are introduced into the dryer' s charge hopper, the widely spaced, adjustable flights continuously direct cuttings to the screen surface. Flights within the cutting dryer create a rolling action that promotes further separation and prevents screen plugging. Under high G-force created by the large cone diameter, liquid and solids separation occurs instantly as cuttings make contact with the finer-mesh centrifuge screen while producing cleaner return fluisd and drier solids discharge. The solids discharged from cutting dryer can also be collected for further disposal, such as thermal treatment. Useful fluids reclaimed by cutting dryer is collected and pumped to decanter centrifuge for final processing and reuses in the active mud system.