Dec 13, 2013

Solids control equipment are mainly used for solids control and solids-fluid separation to achieve drilling mud recycling utilization. Solids control system is an combined system in which equipped with 3 to 7 circulating tanks and configured with 4 phases of purification equipment or solids control equipment, which is fit for 2000 to 7000 meters deep oil drilling processes. The whole solids control system is innovative with conical tanks and installation with mud agitating system to prevent solids from depositing. In addition, the tanks and bins involved in the solids control system will be comparted or unitedrationally depending on the demands of drilling processes. Each of them is connected to another via pipe network in which the valves at the bottom of suction pipes are flexible while opened, but can turn to be a good seal when closed.

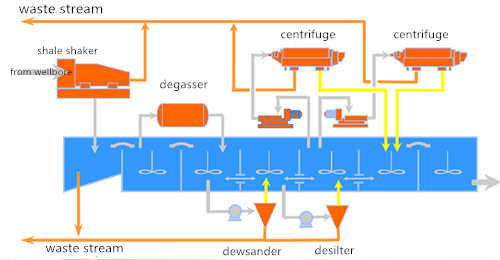

Working Principle of Solids Control System

Solids control equipment are usually combined as an organic composition of solids control system where consists of four phases of solids control equipment, safety equipment, and other auxiliary equipment that are linked together via pipelines as well as mud tanks which are the mud carriers. The arrangement of each solids control equipment is sequenced by separation effects in descending order. The primary drilling fluids flow through diversion pipes into shale shaker, where its larger cuttings (d≧74μm) are separated and the rest flow into mud tank via screen frame. Then the vacuum degasser will suction it into the degasser tank for further gas-fluid separation when there are some gas bubbles in drilling fluids. Afterwards, it will be pumped into desander and desilter for more solids removal by the centrifugal force produced in cones. Solids with diameter between 15-44 μm are to be taken out in desilter and later on, the treated drilling fluids will stream to the mud tank below decanter centrifuge through the pipelines above cones for the last purification. It is pumped into centrifuge by submersible slurry pump ( screw pump ) and its solids with diameter above 2μm will be plucked out by centrifugal force again. All the tanks in the system are linked by built-in pipelines and may be used to contain any kind of drilling mud accordingly in any purification phase. Furthermore, they also work together with jet mud mixer for mud concoction.

As a solids control equipment and system supplier, KOSUN is the professional and pioneer in this industry. With abundant experience, we always keep serious attitude in designning and manufacturing high quality solids control equipment and complete solids control system. Therefore, KOSUN win praise from all our customers.